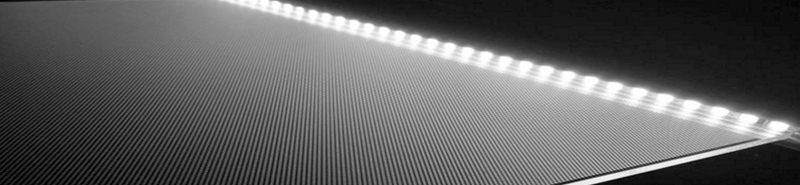

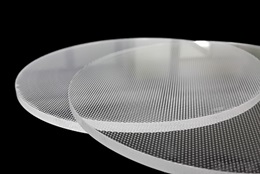

Light Guide Plate (LGP) is a key component in backlight modules, especially for edge-lit designs. It works by guiding LED light from the edge to the front surface through light guide dots, ensuring uniform light distribution. A well-designed dot pattern can greatly improve light efficiency and uniformity.

Popular Materials Used in Light Guide Plates:

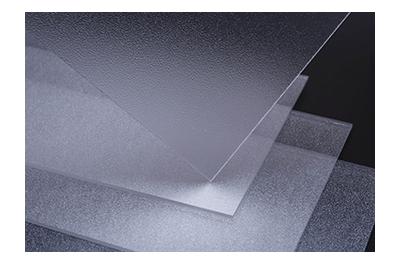

Light guide plates are typically made from optical-grade polymer materials, with light guide dot patterns printed or designed on their surface.

The most common materials are PMMA and PS, each with its own pros and cons:

| Material | Light Transmittance | UV Resistance | Dimensional Stability | Light Efficiency | Cost |

| PMMA (Acrylic) | 92% | Good | - | Good | High |

| Polystyrene (PS) | 89% | - | Good | Lower | Cost effective |

- PMMA LGPs offer higher light transmission and yellowing resistance, making them ideal for premium lighting products. However, they are less dimensionally stable and more expensive.

- PS LGPs with better dimensional stability and lower cost, PS light guide plate has become the mainstream material for indoor panel lights and monitor displays.

Manufacturing Processes for Light Guide Plates:

Common manufacturing processes for light guide plates include the following. Below is a comparison of each process:

| Process | Light Input Design | Suitable For |

| Silk Printing | Flexible | For large-volume customers |

| Extrusion | Fixed | For large-volume customers |

| Laser Engraving | Flexible | For small-volume customers |

| Injection | Flexible | For large-volume customers |

3.jpg)

3.jpg)

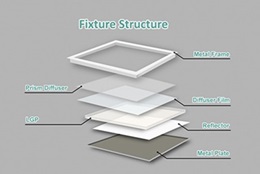

Structure of Light Guide Plate Module:

*Outer Layer: Diffuser Plate & Diffuser Film - Provide excellent scratch resistance and uniformity

*Middle layer: Light guide plate - Most important optical part to perfectly guide the lights throughout the light guide plate.

*Bottom layer: Light reflector film - white reflective film with excellent reflection coating can prevent light leaking and minimize loss of light from light sources.

Applications of Light Guide Plates:

- TV Monitor & Displays

- Lighting: Panel lights, recessed lights, emergency exit signs, illuminated signage

- Inspection Lighting: AOI visual inspection light boxes

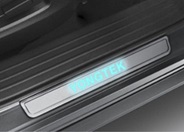

- Automotive Applications: Interior lights, illuminated door sills

- Advertising Signs: Ultra-thin LED light boxes, LED advertising displays

Technical Challenges of Light Guide Plates:

The main challenge in designing light guide plates lies in achieving uniform light diffusion. This makes the design of the light guide dot pattern a crucial factor. A well-designed LGP can provide excellent light uniformity and efficiency.

Why Choose Yongtek As Your Light Guide Plates Supplier?

If you're looking for high-quality light guide plates, we're here to help!

Yongtek specializes in professional light guide dot design and has extensive development experience. We are committed to providing solutions that maximize light efficiency and uniformity.

Our Strengths:

- Diverse Material Options: We offer light guide plates in PMMA and PS materials to meet different customer needs.

- Rich Design and Manufacturing Experience: With years of expertise, we can provide professional advice and help you produce light guide plates that deliver the best performance.

For more information about our products and manufacturing services, feel free to contact us!